Natural graphite is a resource that has a finite and geographically restricted supply. Graphite’s material characteristics, particularly its acoustics, thermal, and electrical conductivity properties, make it an ideal material for use in batteries for energy storage.

With the increase of electrification of homes and vehicles, battery demand and the need for graphite will substantially increase. A sustainably produced form of synthetic graphite from renewable materials that is also low-cost to produce would be ideal.

Novel chemical reactor design with shock wave technology to convert human hair (and potentially wool) into graphite at low temperatures.

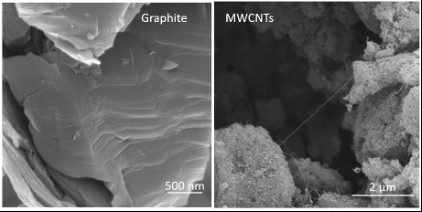

The one-step process has so far been shown to produce battery-grade graphite from human hair. The same reactor is also capable of producing graphene and multi-walled carbon nanotubes (MWCNTs).

Sustainable Manufacturing of Graphitic Carbon from Bio- Waste Using Flash Heating for Anode Material of Lithium-Ion Batteries with Optimal Performance. https://doi.org/10.1002/adsu.202300610